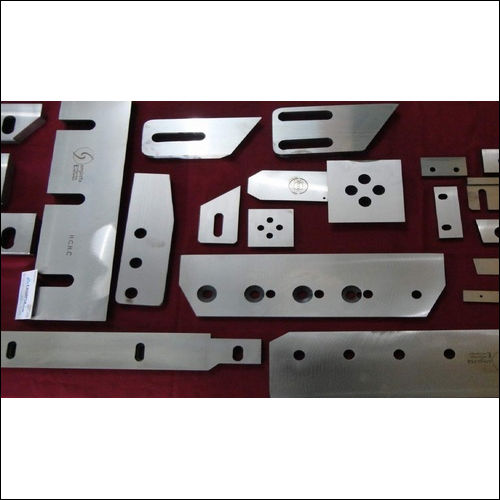

Plastic Cutting Blade

2000-10000 INR/Piece

Product Details:

- Machine Type Plastic Cutting Machine Compatible

- Operation Type Manual/Automatic

- Cutting Speed High

- Tool Type Cutting Blade

- Hardness 55-60 HRC

- Shape Rectangular

- Coating Uncoated

- Click to View more

X

Plastic Cutting Blade Price And Quantity

- 20 Piece

- 2000-10000 INR/Piece

Plastic Cutting Blade Product Specifications

- Cutting Blade

- High

- Manual/Automatic

- Plastic Cutting Machine Compatible

- Rectangular

- Cutting

- 55-60 HRC

- Low

- 100 mm

- Plastic Cutter Blade

- Uncoated

- Manual or Automatic

- 0.02 mm

- Suitable for plastics

- 100 mm

- Rust resistant, Sharp edge, Wear resistant

- High Carbon Steel

Plastic Cutting Blade Trade Information

- 20 Piece Per Day

- 20 Days

Product Description

Backed by a team of highly competent and dexterous team of professionals, we have become a prominent manufacturer and exporter of Plastic Cutting Blade. The offered blade is manufactured using quality tested materials at our state of the art production unit. We have made the blade available in different sizes so as to fulfill the requirements of our clients. Further, this Plastic Cutting Blade is demanded in plastic industry.

Features:

- Perfect finish

- Sturdy construction

- Excellent strength

Exceptional Cutting Performance

The blades high-speed capability and 0.02 mm accuracy make it ideal for applications demanding precision. Its sharp, rust-resistant edge ensures efficient and clean cuts with minimal effort, whether manually operated or paired with an automated machine.

Durable Construction and Design

Made from high carbon steel, the blade delivers long-term durability and resists wear. Its rectangular shape and polished finish facilitate smooth handling and easy cleaning, while the uncoated metallic silver body adds a touch of professionalism to your toolkit.

Versatility in Application

Suited for cutting various forms of plastics, such as sheets, rods, and pipes, the blade adapts to different industrial and commercial settings. Its low-maintenance nature and compatibility with multiple machine types streamline operational workflow for manufacturers and workshop operators.

FAQs of Plastic Cutting Blade:

Q: How do I install the Plastic Cutting Blade on my cutting machine?

A: The blade is designed for compatibility with most plastic cutting machines. To install, ensure the machine is powered off, then securely fit the blade onto the designated slot, following your equipments user manual for proper alignment and safety.Q: What materials can the blade efficiently cut?

A: This blade is engineered for cutting a range of plastics, including sheets, pipes, and rods. Its sharp edge and hardness allow for precise, clean cuts on commonly used industrial and workshop plastics.Q: When should the blade be replaced to ensure optimal performance?

A: Under normal usage conditions, the high carbon steel blade is long-lasting. However, it should be replaced if you notice reduced sharpness, increased cutting force, or any signs of excessive wear or damage.Q: Where can the Plastic Cutting Blade be utilized?

A: Ideal for use in industrial factories, commercial workshops, and manufacturing units, the blade caters to diverse cutting needs. Its suitable for operations involving export, supply, or onsite plastic processing.Q: What is the recommended maintenance process for the blade?

A: Thanks to its polished finish and rust-resistant features, cleaning the blade is straightforward. Simply wipe it down after use with a dry or slightly damp cloth, and ensure it is kept in a dry environment to maintain its edge and longevity.Q: How does using this blade benefit my production process?

A: Its high cutting speed, sharp edge, and precision tolerance of 0.02 mm enhance productivity, reduce material wastage, and ensure consistent results, all while requiring minimal maintenance due to its rust and wear-resistant design.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Cutting Blades' category

|

SANGEETA ENGINEERING ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |